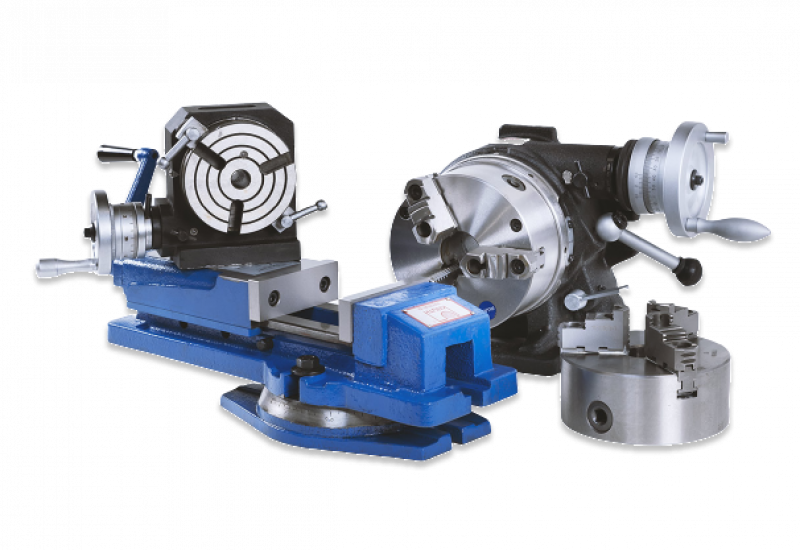

Workpiece Holding

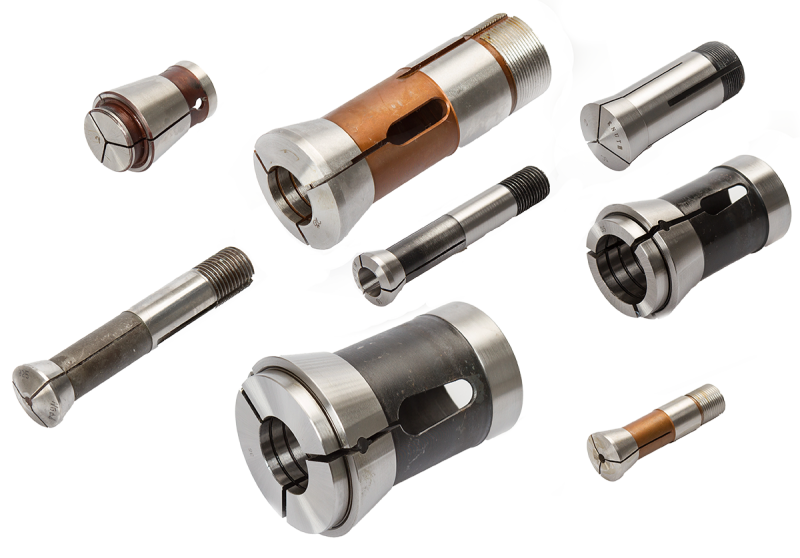

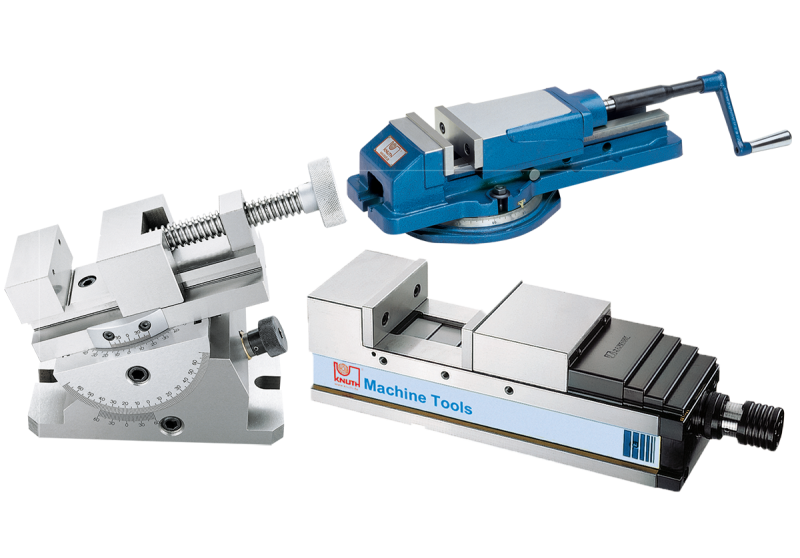

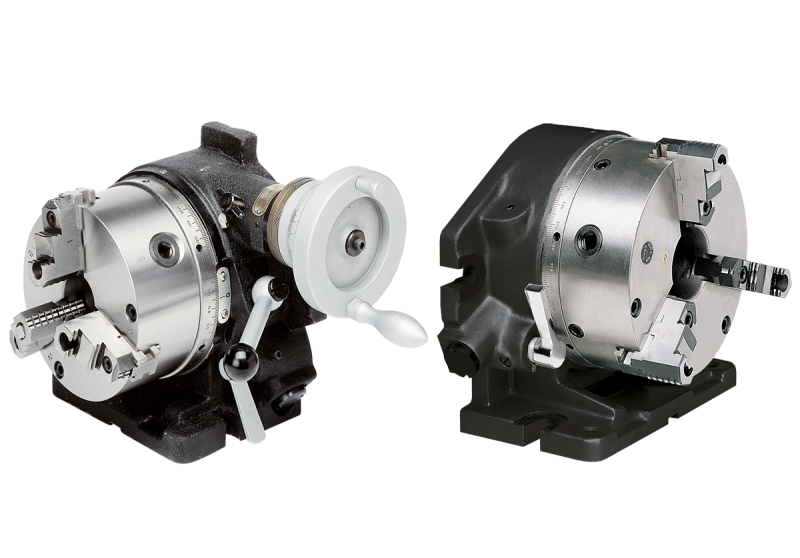

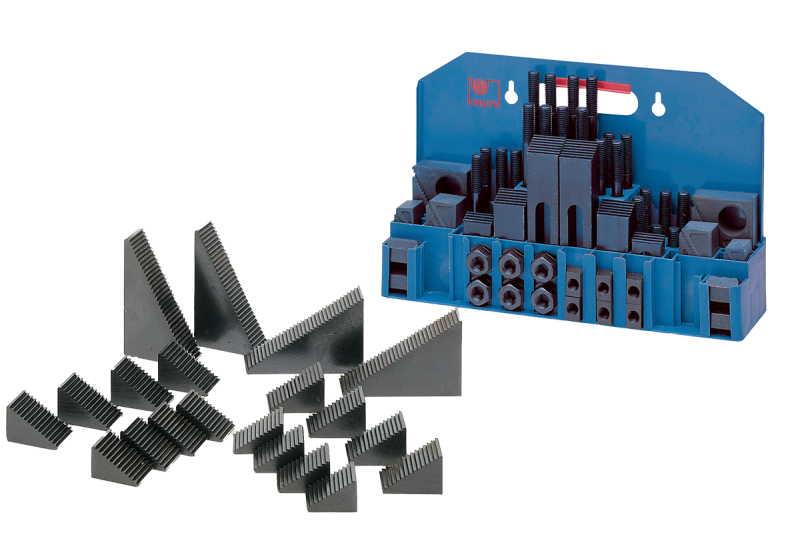

Precise positioning and fixing of the workpiece is crucial for precise machining. Depending on the processing and type of processing required, various fixing elements are available. In addition to the classic vices and clamping tables, dividing devices for precise angular alignment are also available. The range is expanded by clamping tools such as collets and chucks for precisely fitting fixation.

Precise positioning and fixing of the workpiece is crucial for precise machining. Depending on the processing and type of processing required, various fixing elements are available. In addition to the...

read more