Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

The Basic 180 Super is the largest mechanics lathe in the KNUTH Machine Tools catalog and is also one of the heaviest machines in this popular market segment. The large bed width of 206 mm (8 in) and a 30 percent higher total weight have a positive effect on the overall machining quality and enable machining services that also meet industrial requirements. Equipped with position indicator, quick-change holder and other standard accessories, the BASIC 180 Super has been one of our best-selling conventional lathes for more than 20 years.

| Working Area | |

|---|---|

| Center width | 39.37 in |

| Turning diameter over bed | 14 in |

| Turning-Ø over support | 9 in |

| Bed width | 8 in |

| Travels | |

|---|---|

| Travel X-axis | 7 in |

| Travel Z1-axis | 4 in |

| Swing range of top slide | ± 50° |

| Headstock | |

|---|---|

| Spindle speed | 45 rpm - 1800 rpm |

| Spindle bore | 1.5 in |

| Spindle mount | Camlock D1-4 |

| Spindle taper | 5 MT |

| Feed | |

|---|---|

| Feed X-axis | 0.00059 in/R - 0.00866 in/R |

| Feed Z-axis | 0.00169 in/R - 0.02571 in/R |

| Threading | |

|---|---|

| Threading, metric | (37) 0,4-7 mm |

| Threading, whitworth | (28) 4-56 TPI |

| Tailstock | |

|---|---|

| Tailstock quill diameter | 2 in |

| Tailstock taper | 3 MT |

| Tailstock quill stroke | 5 in |

| Tailstock traverse adjustment | ± 0.5 in |

| Drive Capacity | |

|---|---|

| Motor rating main drive | 3.2 Hp |

| Measures and Weights | |

|---|---|

| Overall dimensions (length x width x height) | 77 in x 30 in x 62 in |

| Weight | 1936 lbs |

Basic Functions

Extended Functions

Constant cutting speed

Basic Functions

Extended Functions

Constant cutting speed

High quality German type quick change tool holder to easily switch the tools with a repeat accuracy of 0.0004 in.

Face plate diam. Ø12.6 in

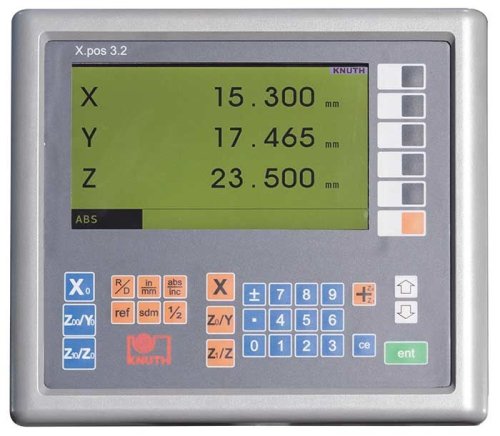

Increases the precision of operations and reduces downtimes spent for part measuring.

Chuck guard with integrated interlock system

Emergency foot brake pedal

Basic Functions

Extended Functions

Constant cutting speed

Explore the range of compatible accessories in stock

We will gladly assist you in making the right decision to achieve your business goals

All machines need an occasional pit stop. With our all-encompassing plans for service, training and installation you always will get the best possible performance from your KNUTH machines.

View Services

Get a first-hand impression at one of our facilities! Many machines in our portfolio are always in stock and available for demonstration.

Book a Demo

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.