Milling Machines

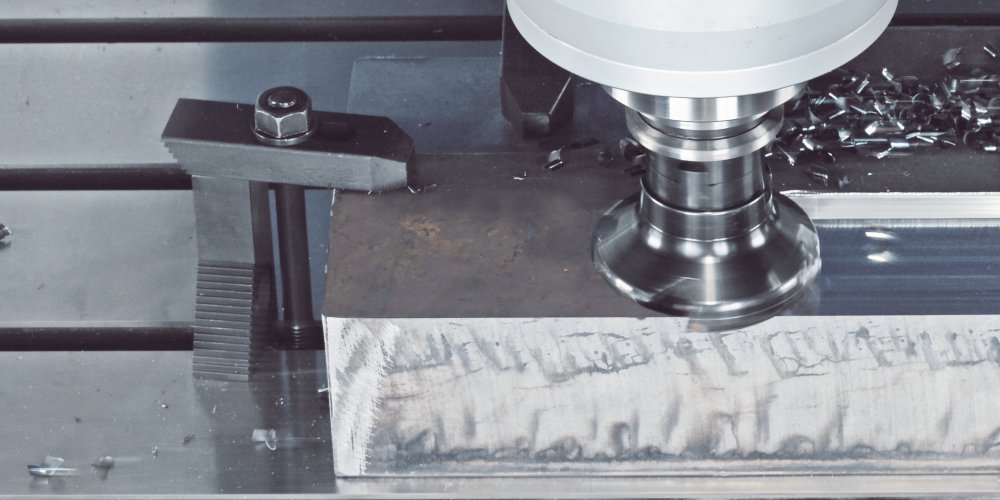

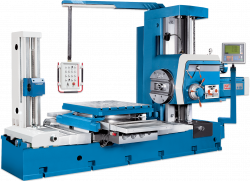

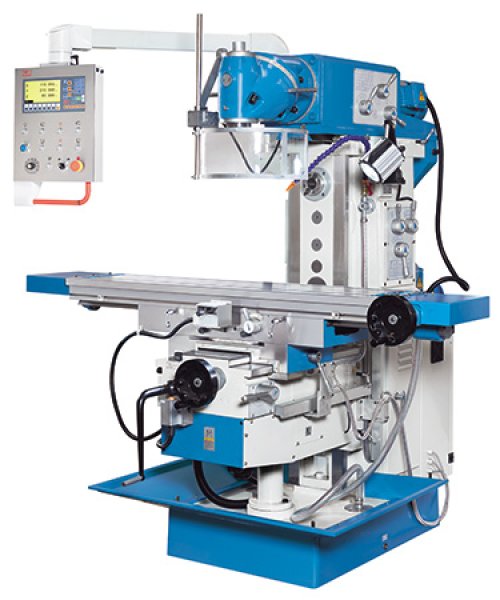

Whether your needs are related to industrial manufacturing, repair workshops or training companies - at KNUTH you will find your conventional milling machine or CNC milling machine for sale. Milling machines are suitable for creating surfaces, grooves, pockets and precise holes. With the positioning of 3 axis all conventional and CNC milling machines and CNC milling centers enable the production of complex spatial contours such as gearbox housings.

Whether your needs are related to industrial manufacturing, repair workshops or training companies - at KNUTH you will find your conventional milling machine or CNC milling machine for sale. Milling m...

read more