Wire Cut EDM

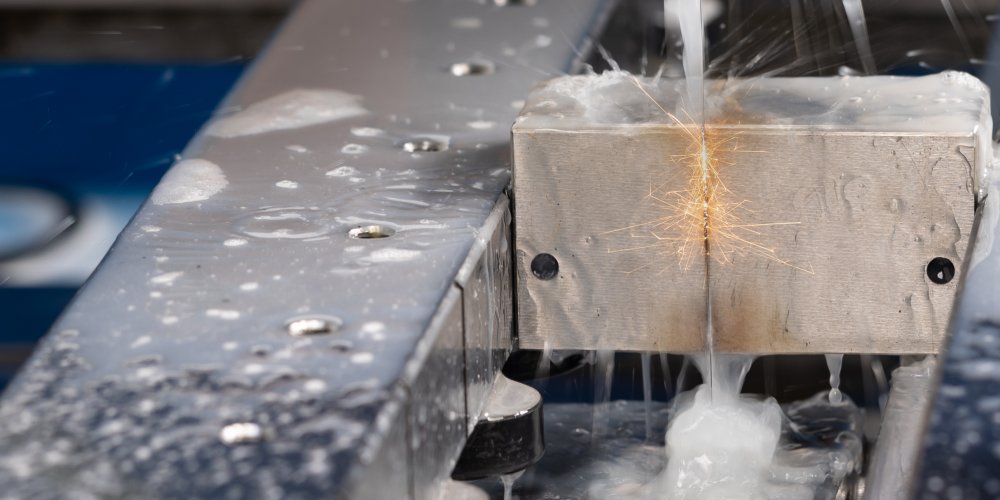

Our high-speed wire EDM machines produce the most delicate structures from even high-alloy or hardened tool steel without deformation or micro-cracks. The material is thermally removed by the electrical discharge between the continuous wire electrode and the metallic base. Deionized water as an active medium ensures a sufficiently large working gap. Every KNUTH wire EDM machine features tables with 2-axis path control and processes workpieces up to 47 inches in length and 1,760 pounds in weight.

Our high-speed wire EDM machines produce the most delicate structures from even high-alloy or hardened tool steel without deformation or micro-cracks. The material is thermally removed by the electric...

read more