Chucks and Accessories

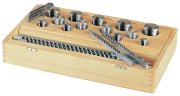

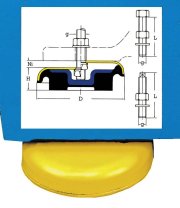

Lathes use chucks for the clamping of workpieces. Lathe chucks and collet chucks come in various diameters and are available with a cast-iron body for manual operation, or in a steel body for constant speed operation. Many sizes are available in 3-jaw and 4-jaw designs. A firm hold of the workpiece and also precise concentricity are very important properties. Our offer is rounded off with workpiece-specific precision collets and soft lathe jaws. Lathe chucks can be selected specifically for the lathe’s mount system, or they can be mounted to the machine via a flange.