Conventional Cylindrical Grinders

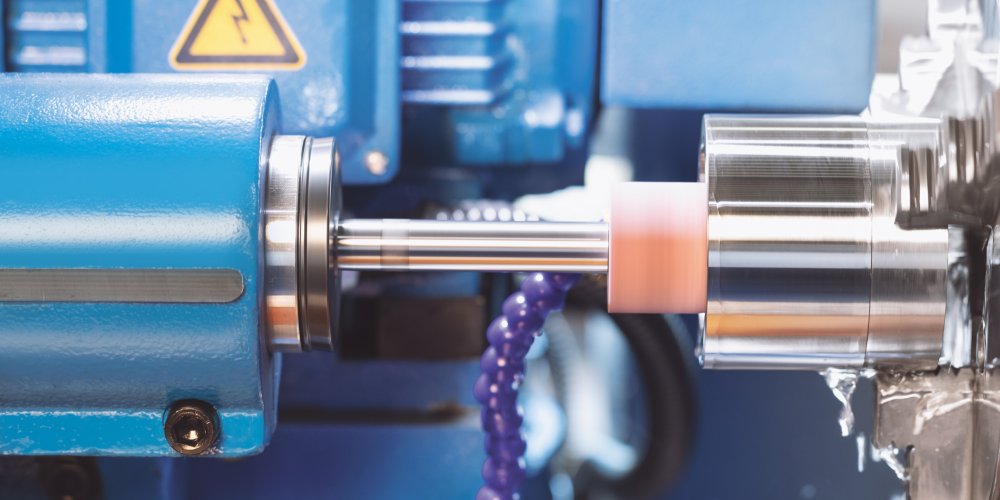

KNUTH's cylindrical grinders feature extreme precision and excellent surface finish. With a precisely balanced grinding wheel that is fed radially, low heat is generated via a flood coolant system, along with good chip removal. Featuring both outer and inner grinding capabilities, these conventional cylindrical grinders are an economical way to achieve the manufacture of precise shapes and high surface finish.

KNUTH's cylindrical grinders feature extreme precision and excellent surface finish. With a precisely balanced grinding wheel that is fed radially, low heat is generated via a flood coolant system, al...

read more