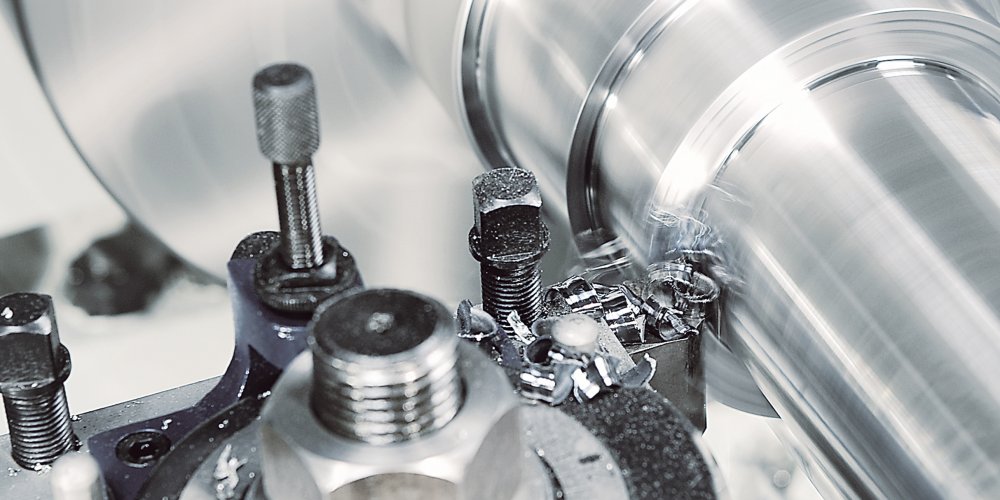

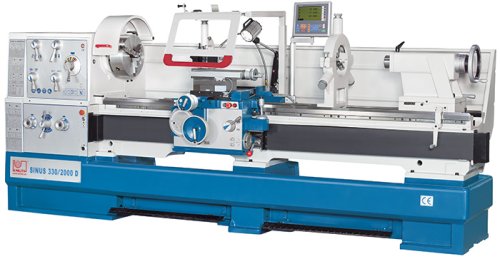

Conventional Horizontal Lathes

KNUTH's conventional lathes are ideal for workshops, repair shops, job shops, as well as for educational purposes. Our lathes feature extensive standard equipment and features and they are also flexible to the demands of industry. In addition, KNUTH offers servo-conventional lathes that provide a precision similar to CNC in the way of integrated electronics and servo drives, without the expense of a CNC operating system. KNUTH's large bore lathes are ideally suited for large pipes and/or heavy workpieces.

KNUTH's conventional lathes are ideal for workshops, repair shops, job shops, as well as for educational purposes. Our lathes feature extensive standard equipment and features and they are also flexib...

read more