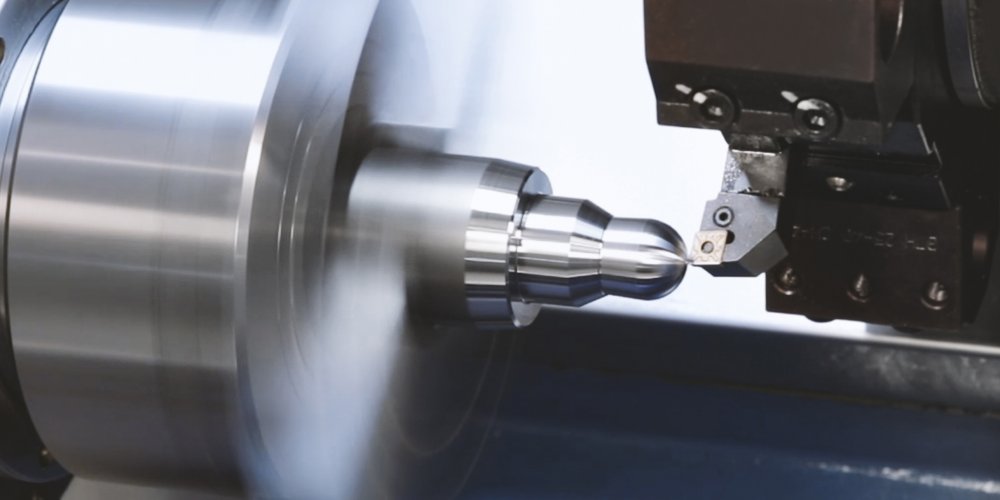

CNC Slant Bed Lathes

These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high stiffness and precision. As a CNC slant bed lathe it is particularly suitable for reliable and efficient turning in series. Powerful drive and a stable fast tool changer also guarantee economic production.

These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high...

read more